Lead-free (Sn) perovskites

Fast and stable recipes; mitigation of Sn(II)→Sn(IV).

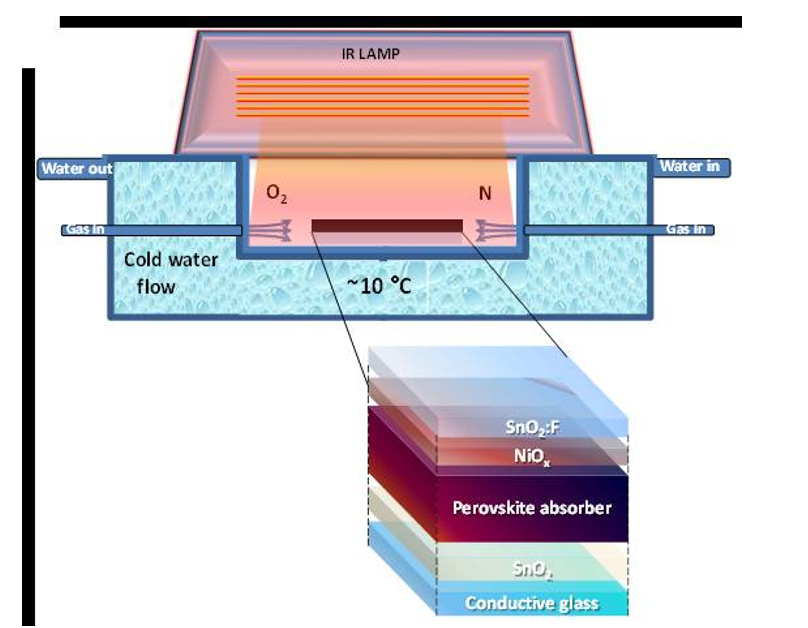

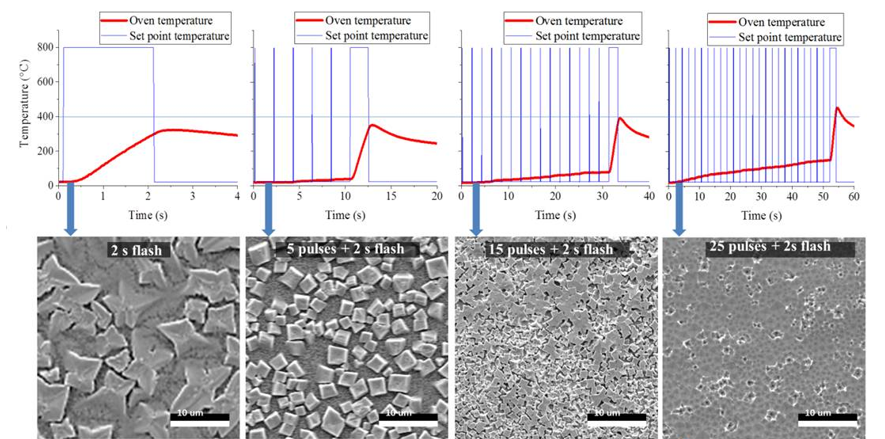

Flash Infrared Annealing (FIRA) is a revolutionary photonic thermal process designed for the rapid crystallization and sintering of solution-processed thin films. Unlike conventional ovens that require minutes to hours and expose materials to high thermal budgets, FIRA operates in time windows ranging from 20 milliseconds to just a few seconds.

Within this ultrafast timeframe, wet precursors transform into highly ordered crystalline structures—without the need for toxic antisolvents. By leveraging high optical power, programmable pulse shapes, and selective heating, FIRA delivers films that are:

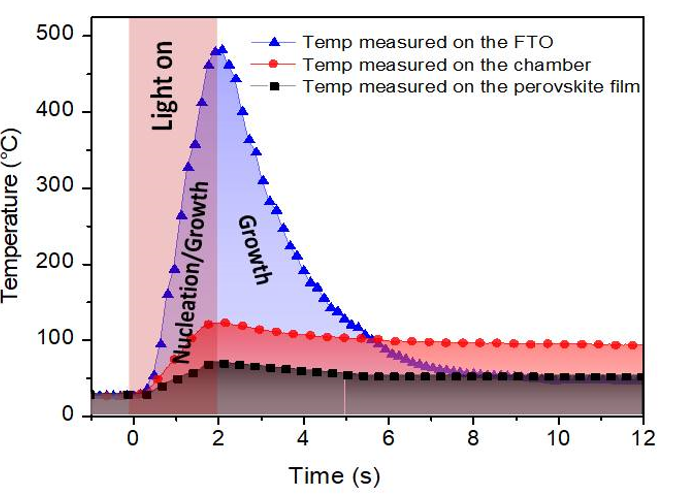

At the core of FIRA lies infrared pulse heating. Conductive layers such as FTO substrates absorb IR light and rapidly transfer thermal energy into the film. By carefully adjusting pulse duration (20 ms – 2 s) and intensity, users can:

This process is selective: inorganic layers absorb the IR energy while underlying temperature-sensitive polymers remain protected. The result is a gentle yet powerful method to build high-performance thin-film stacks that conventional thermal treatments cannot achieve.

To bring this groundbreaking method to the research community, AMBIMETRICS, through its Laboratory of Engineering and Electronic Instrumentation (LI2E) and in collaboration with leading universities, has developed the AmbiFIRA‑Lab system.

It is more than an annealing tool. AmbiFIRA‑Lab is a research accelerator, enabling laboratories to explore new materials, optimize thin-film growth, and scale successful recipes from benchtop coupons to pilot-line modules.

Unlike large, industrial annealing systems that are costly, complex, and designed only for mass production, AmbiFIRA‑Lab is compact, accessible, and engineered for research environments.

AMBIMETRICS is currently extending the platform with AmbiFIRA‑Scale, an industrial version of the technology. AmbiFIRA‑Scale is designed as an integration-ready module for wet-coating lines, such as slot-die, inkjet, and roll-to-roll processes.

👉 AmbiFIRA‑Lab is your gateway to mastering FIRA in the lab. AmbiFIRA‑Scale is your bridge to industrial success.

We are a technology-based company with more than 30 years of experience in turnkey projects. Our track record is centered on R&D, with several patents and collaborations with universities and leading research centers. From LI2E we design and manufacture high-tech equipment for research, integrating electronics, control, sensing, and regulatory safety.

Custom electronics and sensors · Test benches · Process control · In-situ QA · CE documentation.

LI2E is a department of AMBIMETRICS. If you want to know more about us, click here →

Good design and good ideas need good execution. LI2E knows how to execute high‑tech projects that solve real‑world problems.

Fast and stable recipes; mitigation of Sn(II)→Sn(IV).

FIRA module after coating; uniformity and in-line QA.

Top-layer crystallization without damaging silicon.

A curated selection of references related to perovskite processing, photonic annealing, and rapid thermal strategies:

Tell us about your case (R&D, pilot or production). We will prepare a proposal or demo according to your needs.

Or write us directly at sales@fira.ambimetrics.com

Made in Europe · Spain

Support for universities, research centers and industrial companies.